Tuesday, October 28, 2008

Project Changing

My anaerobic digester project has changed direction. I still have two digesters in operation at my house but my main goal is now to figure out how big of a building can be built on our current campus to reduce the cost and amount of natural gas that the school uses per year. I am essentially just trying to figure out the pure logistics of an anaerobic digester at school. This may simple include blue prints or it might be more advanced. For example I might have the opputunity to talk with the architects in Seattle who designed our two new buildings. A huge step would be to speak with Intrepid Technology & Resources about coming to look at our campus. The typical cost of this is generally between $5,000 and $20,000.

Tuesday, October 21, 2008

Intrepid Technology & Resources, Inc.

Intrepid Technology & Resources, Inc. is a company in Idaho Falls, Idaho. They are responsible for the construction of biogas generators in Rupert, Idaho and Wendell, Idaho. (Intrepid Technology & Resources, Inc. uses the term biogas generator instead of anaerobic digester.)

I am determining the questions I want to ask them about a possible generator at school. My main goal here is to see if it is even possible to fit a generator on campus and whether or not the waste from the Horseman's Center will work for a generator.

Link to ITR, Inc.:

http://www.intrepid21.com/index.htm

I am determining the questions I want to ask them about a possible generator at school. My main goal here is to see if it is even possible to fit a generator on campus and whether or not the waste from the Horseman's Center will work for a generator.

Link to ITR, Inc.:

http://www.intrepid21.com/index.htm

Thursday, October 16, 2008

Sunday, October 12, 2008

Gas Production

My medium-scale digester is now in progress. I added about 3 liters of cow manure into the digester container the other day to let the process begin. My digester has not created any methane as of now because the bacteria must consume all of the available oxygen first. I am hoping to see methane production begin later this week.

The design and construction plans that I used worked very well and the system is very manageable. I don't have to worry about any of it spilling or leaking in my house. The last time I exchanged email between an employee of the Pembina Institute, he said that a copper pipe that has the end of it crushed to form a small hole will work just fine for the gas jet that I will use in place of a Bunsen burner. (The original plans had the outlet hose connect directly to a Bunsen burner).

The design and construction plans that I used worked very well and the system is very manageable. I don't have to worry about any of it spilling or leaking in my house. The last time I exchanged email between an employee of the Pembina Institute, he said that a copper pipe that has the end of it crushed to form a small hole will work just fine for the gas jet that I will use in place of a Bunsen burner. (The original plans had the outlet hose connect directly to a Bunsen burner).

Thursday, October 9, 2008

New Digester

My medium-scale digester is now complete and I have put the cow manure into the container. The cow manure was not hard to work with but when it was right up in my face combined with the smell, it made stuffing the manure into the container a little strange. The digester is now in one of the warmer areas of my garage so that it begins to work as quickly as possible. I will have to wait for a few days for the bacteria to consume the oxygen. Once the oxygen is consumed the bacteria will begin producing methane.

My research has shown me somewhat of an outline of how anaerobic digesters work.

1) Bacterial hydrolysis (chemical breakdown of a compound due to reaction with water) of materials --> breaks down insoluable organic polymers (carbohydrates.)

2) Acidogenic bacteria convert sugars and amino acids to carbon dioxide, hydrogen, ammonia and organic acids.

3) Acetogenic bacteria convert these organic acids into acetic acid and more ammonia, hydrogen and carbon dioxide.

4) Methanogenic bacteria convert ammonia and hydrogen to methane and carbon dioxide.

(http://www.nationmaster.com/encyclopedia/Anaerobic-digestion)

My research has shown me somewhat of an outline of how anaerobic digesters work.

1) Bacterial hydrolysis (chemical breakdown of a compound due to reaction with water) of materials --> breaks down insoluable organic polymers (carbohydrates.)

2) Acidogenic bacteria convert sugars and amino acids to carbon dioxide, hydrogen, ammonia and organic acids.

3) Acetogenic bacteria convert these organic acids into acetic acid and more ammonia, hydrogen and carbon dioxide.

4) Methanogenic bacteria convert ammonia and hydrogen to methane and carbon dioxide.

(http://www.nationmaster.com/encyclopedia/Anaerobic-digestion)

Wednesday, October 8, 2008

Medium-scale Digester is Complete

My medium-scale anaerobic digester is now complete. The construction was very simple compared to finding the required materials. I will put the cow manure into the digester container this afternoon to let the system begin to develop the bacteria that will digest the cow manure. The construction plans that I found on (http://www.re-energy.ca/t-i_biomassbuild-2.shtml) proved to be very helpful. I sent this group an email and they replied very quickly with very helpful answers and even diagrams to help me build part of my digester.

Monday, October 6, 2008

New Materials for Digester

How hard can it be to find the following materials for a medium-scale anaerobic digester?

- -Used 18L clear plastic water bottle

-Large Mylar helium balloon

-Plastic water bottle cap (with the "no-spill" insert-see photo)

-Copper tubing (40 cm long, 6.5mm (1/4") inside diameter)

-T-connector for plastic tubing (barbed, 6mm or ¼" long)

-1 cork (tapered, 23mm long)

-Clear vinyl tubing (1.5 m long, 4mm or ¼-inch inside diameter)

-2 barb fittings (¼" x ¼")

-Ball valve (1/4")

-6-8L manure pellets (goat, sheep, llama, rabbit, or other ruminant)

-Rubber gloves

-Large plastic funnel (can be made from a 4L plastic milk jug with bottom removed)

-Wooden dowelling or stick (30 to 50 cm long, 2-3 cm thick)

Materials for Medium-scale Digester

I have found materials and construction plans for a medium-scale digester thanks to http://www.re-energy.ca/t-i_biomassbuild-2.shtml. This site has proved to be one of the best resources for this medium-scale digester because of the relatively detailed construction plans and the materials and tools required.

Wednesday, October 1, 2008

New Material for Digester

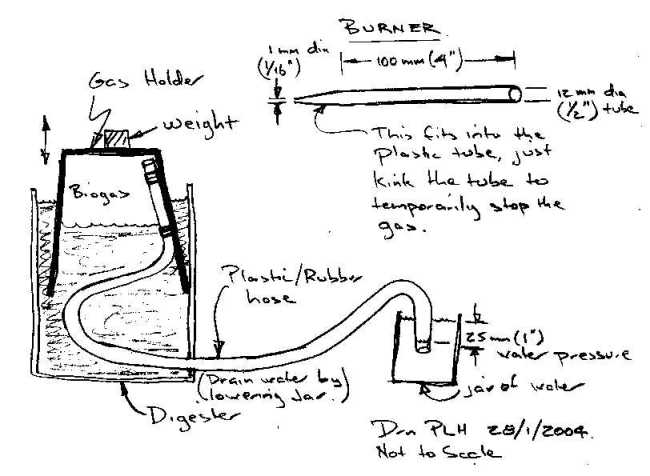

I have just recently received another email from Paul Harris of The University of Adelaide in Roseworthy, South Australia on the topic of what is best for an anaerobic digester. His reply to my email message writes:

"Pig or cow manure is best for bacteria (I have used pig manure). Or you may

be able to get some sludge from a sewerage treatment works or an operating

digester if there is one nearby.

You should burn the gas if possible, as methane is 23 times worse as a

greenhouse gas than carbon dioxide (not that you are making a huge amount!).

I have found that a 12mm (1/2") tube (metal!) makes a good burner for small

scale by using a 1mm (1/16") diameter gas jet and low pressure supply -

about 25mm (1") water pressure (there is a sketch on the web page http://www.adelaide.edu.au/biogas/fair/). All I do is run a tube from my

digester to the burner."

My next goal is to find a pretty local ranch or farm that I can get some cow manure from. I believe that this should be relatively easy to accomplish.

After that, my main problem is determining what type of gas is actually being produce and whether or not it is safe to burn. I do not want to have a flame any where near my project if it turns out that the gas will explode rather than burn.

"Pig or cow manure is best for bacteria (I have used pig manure). Or you may

be able to get some sludge from a sewerage treatment works or an operating

digester if there is one nearby.

You should burn the gas if possible, as methane is 23 times worse as a

greenhouse gas than carbon dioxide (not that you are making a huge amount!).

I have found that a 12mm (1/2") tube (metal!) makes a good burner for small

scale by using a 1mm (1/16") diameter gas jet and low pressure supply -

about 25mm (1") water pressure (there is a sketch on the web page http://www.adelaide.edu.au/biogas/fair/). All I do is run a tube from my

digester to the burner."

My next goal is to find a pretty local ranch or farm that I can get some cow manure from. I believe that this should be relatively easy to accomplish.

After that, my main problem is determining what type of gas is actually being produce and whether or not it is safe to burn. I do not want to have a flame any where near my project if it turns out that the gas will explode rather than burn.

Subscribe to:

Posts (Atom)